Esor Pipelines focusses on the construction and rehabilitation of onshore pipelines and operates mainly in the water, stormwater, sewer and gas and petrochemical sectors.

The division has specialist experience in laying and welding steel pipelines as well as those made from glass fibre reinforced polyester (GRP), concrete, PVC, ductile iron, HDPE and fibre cement. In addition, pipeline refurbishment is undertaken including mechanicals, lining and coatings.

The key distinguishing features include a vast track record and experience in continuous welded steel pipelines, focussing on large bore pipeline projects. The flagship contract include the BG3 project for Rand Water in delivering water from the Vaal dam, a distance of 8,6 km, in a 3 500mm diameter steel pipe to the canal feeding Zuikerbos Pump Station.

Lebalelo

The construction of a 500mm ND spigot and socket pipe approximately 16km in length.

The construction of approximately 26 pre-cast air valve chambers.

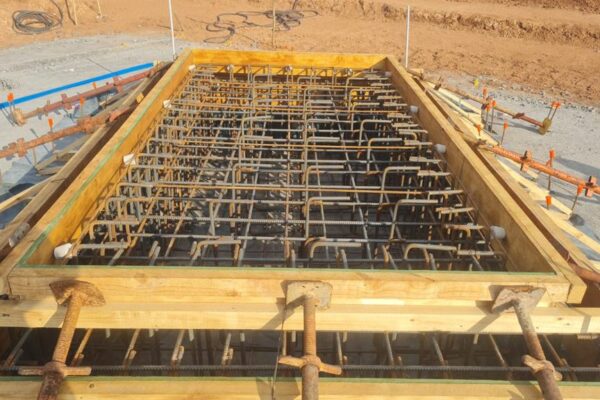

The construction of approximately 19 cast in-situ scour valve chambers.

The construction of approximately 3 off-take chambers.

The construction of in-line valves at various scour valve chambers.

The construction of a new pump station at Spitskop

The project is situated to the south of Steelpoort and approximately 45km due south-west from the CBD of Burgersfort adjacent to the R37 Polokwane/Burgersfort Road

Contract Amount: R 241 336 992.24 (exclusive of VAT)

Rehabilitation of Nagle Aqueducts 1 & 2 due to April Flood Damage

During the severe floods experienced in April 2022, Umgeni Water’s bulk raw water infrastructure, particularly that servicing the Durban Heights Water Treatment Plant (WTP), was severely damaged. Raw water is transferred from Nagle Dam to Durban Heights WTP via a series of gravity tunnels and siphons colloquially known as the “Nagle Aqueducts”. Most of these systems were constructed in the 1960/70’s. Umgeni Water is thus currently entirely dependent upon its Aqueducts 3 and 4 and the Shaft Pumps for raw water supply to Durban Heights WTP. Both Aqueducts 3 and 4 and the Shaft pumps are operating below design capacity. The infrastructure allied to this project accounts for some 80% of Umgeni Water’s sales.

6 major breaks were initially identified where catastrophic failure of the system took place, along with various other incidental damage sites being identified that required rehabilitation.

Esor Construction was awarded the Contract in June 2022 as a full design and build turnkey project. Esor appointed Mbona Saunders and Wium (Pty) Ltd (trading as MSW Consulting) as its design consultant. MSW have a long record of working with Umgeni Water and have a sound knowledge of the Umgeni Water Infrastructure, which has been essential in assessing solutions for the damaged sections of the system.

As part of its rehabilitation strategy Umgeni Water included the construction of a new rising main at the Inanda Dam Pump Station to supplement supply to Durban Heights WTP while the repairs sites were being worked on.

The Contract was awarded to Esor Construction in June 2022 and is to be completed by December 2023

Steenbras Dam

Re-alignment of the Steenbras 810mm bulk water pipeline, Old faure, Mfuleni and Driftsands

Client: City of Cape Town

Scope: Excavate and lay of approximately 4500m of 850mm dia cement mortar steel pipeline

Project Value excl VAT R37.65 million